Basic Info

Model No.: 3MK3112B

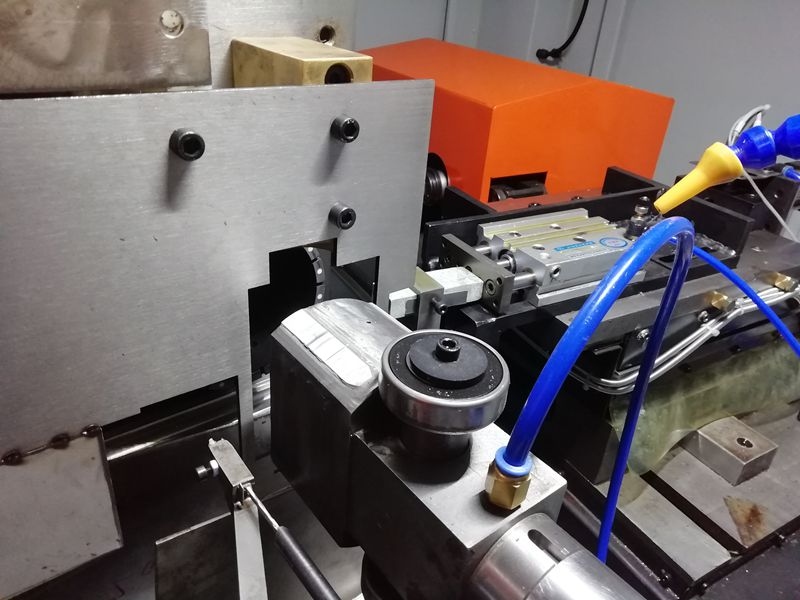

Product Description

1. Mitsubishi PLC control system is adopted in the control system, and touch screen is adopted in the grinding dynamic display.

2. The feed system is driven by mitsubishi ac servo motor + ball screw, which can realize high precision, fast driving and slow feeding movement with high sensitivity, and the minimum resolution is up to 0.0002mm.

3. The reciprocating system can realize ac frequency conversion speed regulation.

4. Grinding frame and workpiece feed system adopt ultra-precision, pre-load cross roller guide with good rigidity and long service life.

5. The workpiece spindle adopts sleeve structure, which can be adjusted by frequency conversion.

Machining accurancy(UC208):

|

No. |

Item |

Accuracy requirements |

|

1 |

Roundness |

20%~30% better |

|

2 |

Surface roughness |

≤0.04 |

|

3 |

rhythm |

16 second |

Contact Person: song

Phone:86-0373-5805777

Fax:

Address: No.2 Wenyan Road,Red flag Industrial Park,Xinxiang,Henan

Sweep wechat

© 2019 CHINA WAY. All Rights Reserved. Xinxiang Sunrise CNC Bearing Equipment Co., Ltd., Inc. All rights reserved. site map. sitemap.html